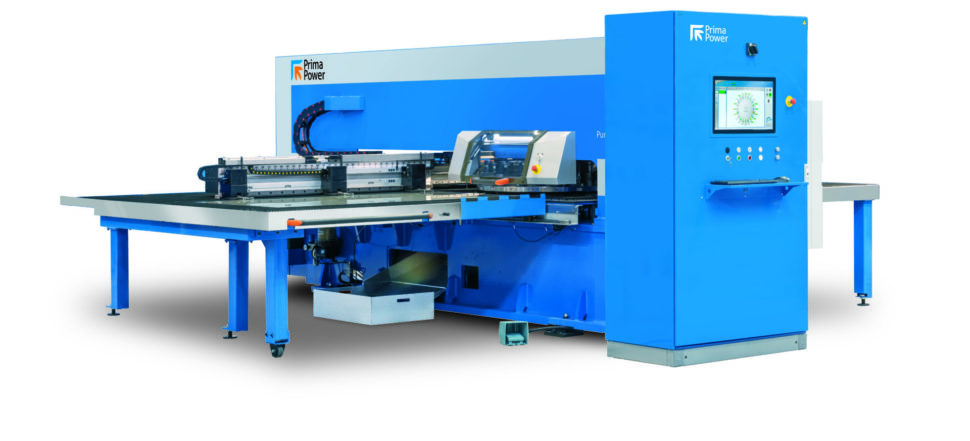

Prima Power has been gathering experience in the development of turret punch presses since the early 1980s. Therefore, their knowledge helped them realize that even though modern machines are very different, the targets for the customer are generally speaking the same: ease of operation and higher productivity.

With this in mind, Prima Power designed the Punch Sharp turret punch press to offer versatile tooling capacity made easy to utilize. In addition, machine HMI control and user interface software with touch screen panel ensure fast set up and convenient operation.

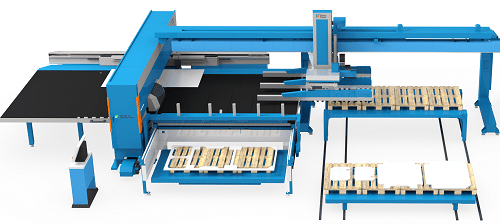

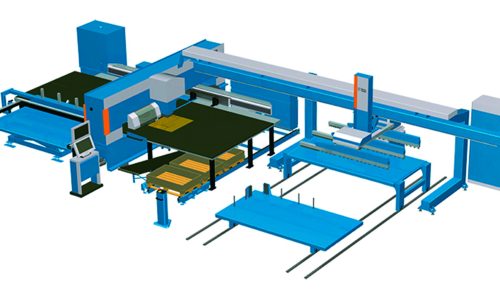

By and large, the core of the Punch Sharp turret punch press is the principle of modularity and connectivity. Therefore, Punch Sharp can load sheets and remove parts and skeletons unattended with basic Prima Power automation with only a tiny amount of floor space required.

Punch Sharp is one of the only turret punch presses on the market which can be eventually upgraded to a laser combi machine. In other words, the Prima Power Punch Sharp can become a Combi Sharp and adds a level of modularity that no other manufacture can offer. To achieve this, the upgrade is performed by adding fiber laser equipment, replacing the work table, and including part and scrap conveyors for laser cut parts.

In brief, Punch Sharp furthermore offers significant advantages in productivity, operational convenience, and compatibility with several automation solutions.

Features of the Punch Sharp Turret Punch Press

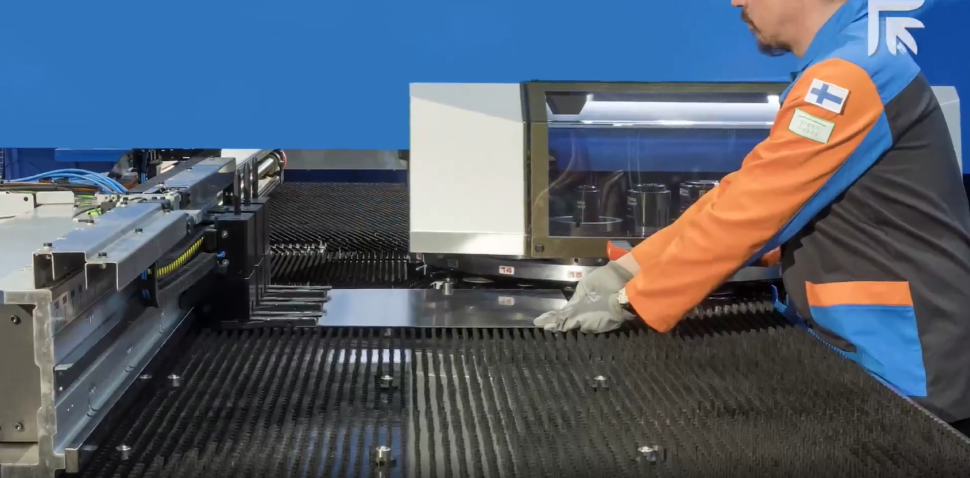

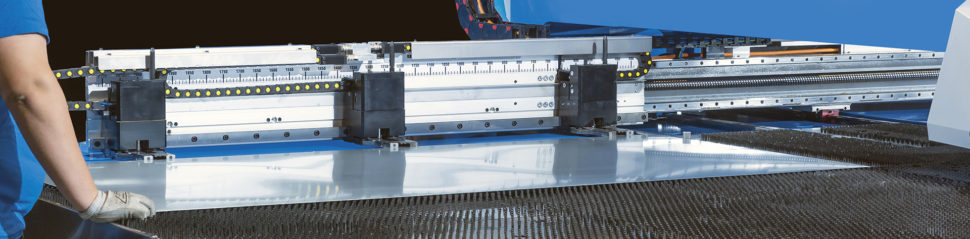

User-Friendly Easy Loading; Manual loading from either the A-side or B side or entirely automated by using optional automation cells

Low Power Use; Cost-efficient servo-electric punching is around 60% cheaper than other technology.

Programmable Clamp Movement; Programmable Clamp Setting ( PCS ) allows 100% sheet utilization.

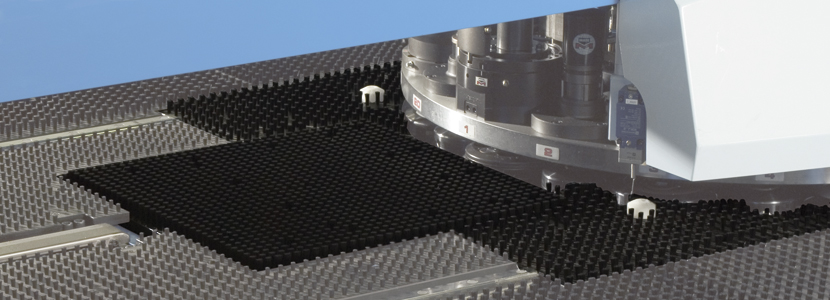

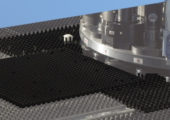

Scratch Free Operation; Automatic brushes move vertically from underneath to protect the back of the material during the punching or forming cycle

Upforming; Upforming cylinder to create forms of almost endless types

Android-based Tulus Mobile application; Provides instructions for tool set-ups and other operational tasks.