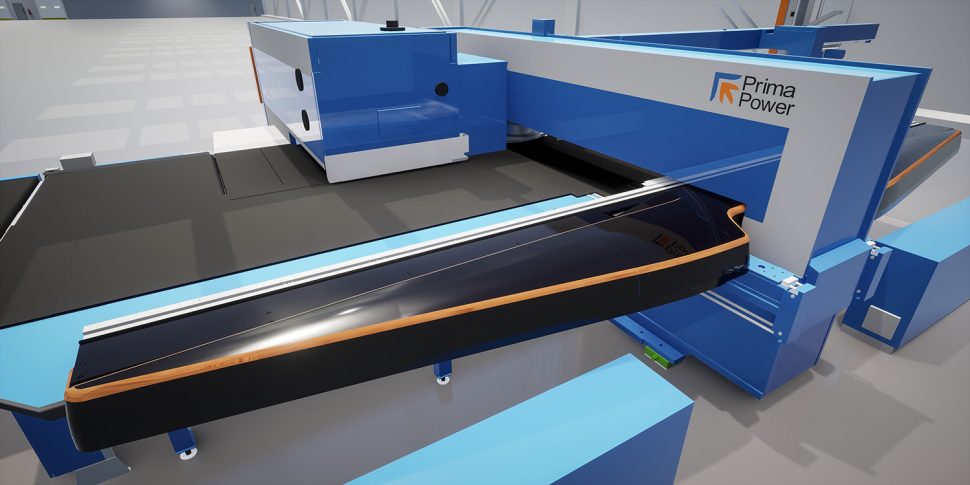

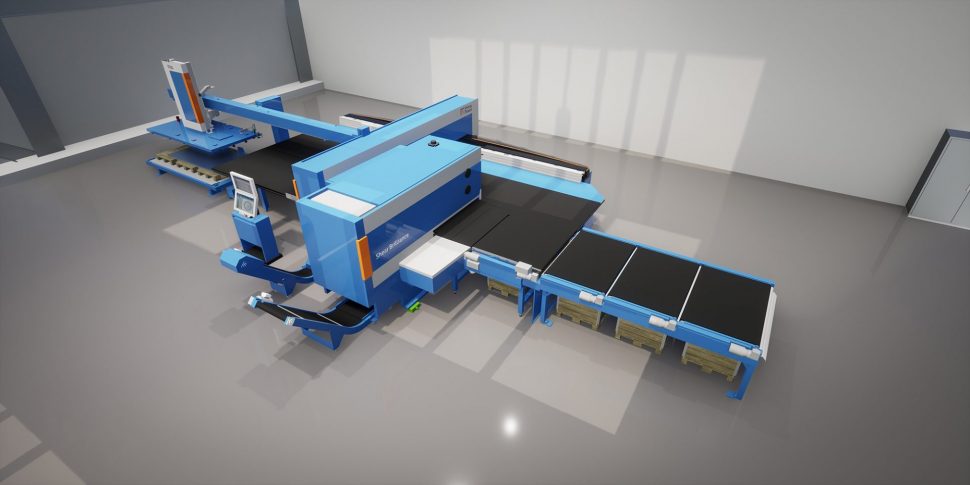

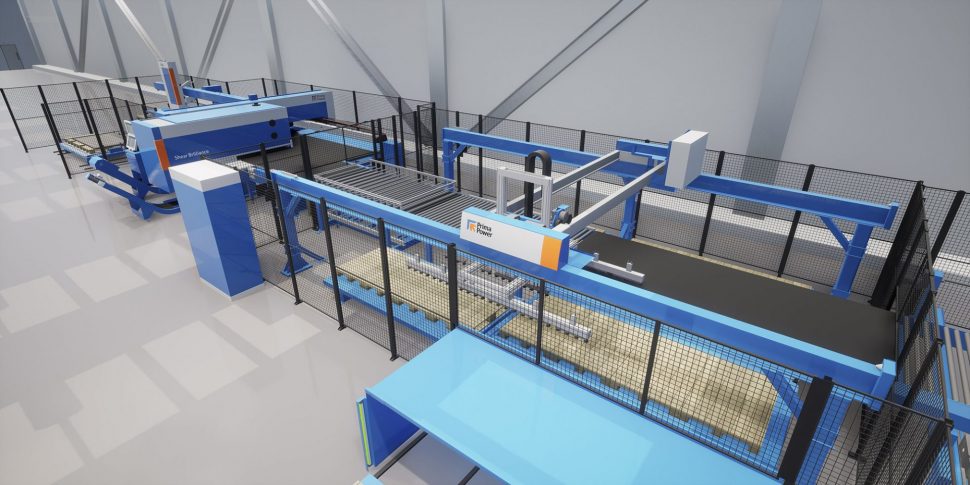

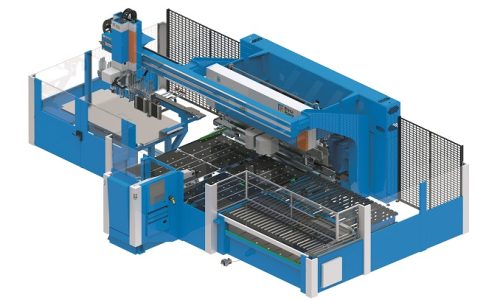

Prima Power Shear Brilliance combines composite materials, servo-electric technology, and linear drives to achieve impressive performance while keeping power usage to the absolute minimum. Due to these features, Shear Brilliance has the highest level of productivity on the market in a versatile, flexible, and modular solution.

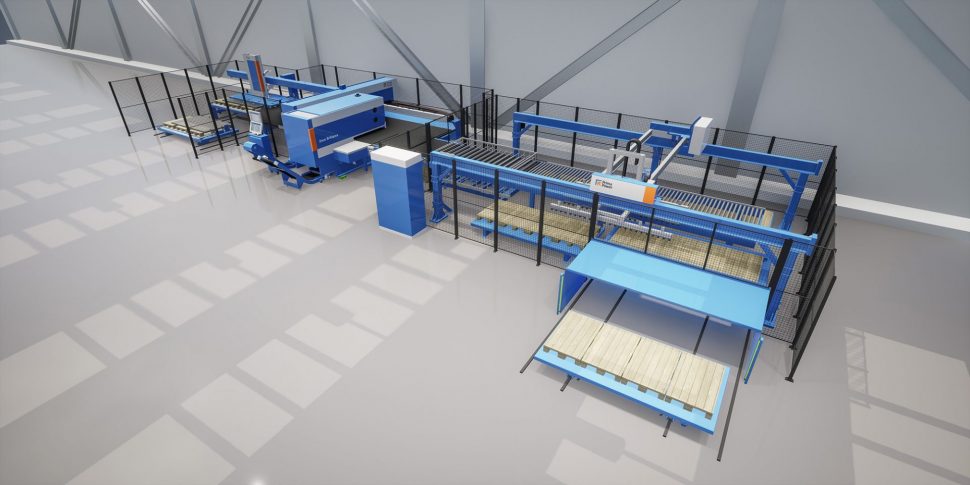

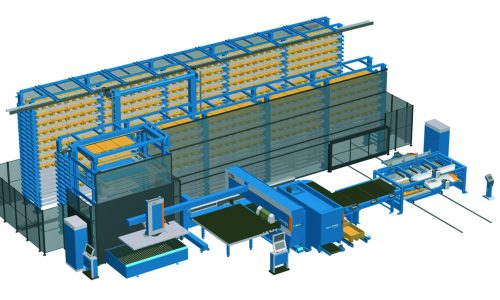

The integrated turret punch-shearing concept has been led by Prima Power ( previously Finn Power ) since 1987, with more than 3,000 integrated punching-shearing cells installed worldwide. Above all, the inherent benefits of the process translate into a superior manufacturing economy in most varied applications where Shear Brilliance is used as an independent cell or as a critical unit of a more extensive Flexible Manufacturing System ( FMS ).

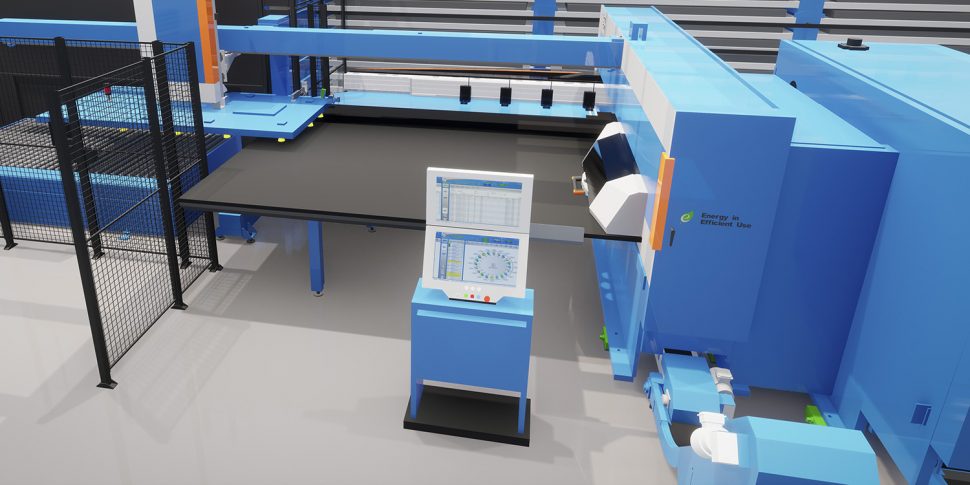

The completely servo-electric Shear Brilliance features linear drive technology in sheet positioning, raising manufacturing speed and productivity to new levels.

The Prima Power right angle shear is extremely fast in operation. Programmable blade height and automatic stroke depth adjustment optimize shearing. The Shear Brilliance features automatically controlled blade speed, designed for maximum speed and productivity. Together with automatic shearing modes, this optimizes operation speed.

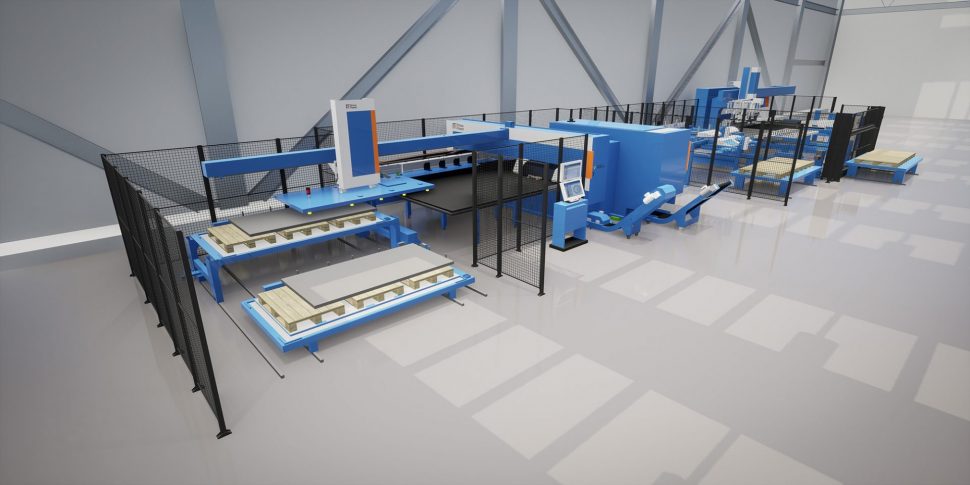

Shear Brilliance is easily connected to automation systems to automate the material and part flow and increase the output.

Highlights of the Shear Brilliance Turret Shear Combo

- Loading completed in hidden time results in more production time available

- Hit speeds up to 1,300 hpm – fastest hit rate available in the market for punching/shearing full format sheets

- 3,100 mm common working area – punching and shearing without repositioning

- More force ( up to 33 tons) – Complicated contours can be punched with one hit

- High tooling capacity – huge savings in set-up times, flexibility in production

- Supreme positioning speed, accuracy, and precision – Time savings and improved quality during processing

- Robust and well-proven ‘O’ frame – perfect tool alignment over a long period of time

- Modular automation – grows with your business to improve production capabilities