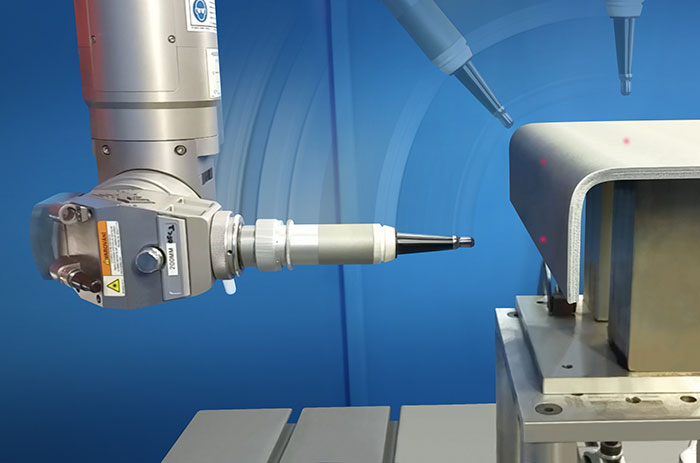

The direct energy deposition solution for high accuracy and productivity.

Combining the flexibility and modularity of the long established Laserdyne laser processing platform with efficient integration and control synchronisation of the different additive sub systems. With automation options and next to you for process configuration and application support, the Laserdyne direct energy deposition machines are a competitive and reliable deposition machine tailored to your requirements.

The Prima Electro high efficiency laser sources, the low operation and maintenance costs along with the easy user access and simple operation can guarantee an excellent performance of your investment.

- High accuracy and a reliable process with high deposition rate

- Innovative laser head

- 3-axis CNC system with embedded multiple crash protection

- Efficient use of resources and excellent end-part properties

Highlights of the Laserdyne Direct Energy Deposition Systems

- Flexible

Designed to accommodate different laser processes, the product is well suited to metal additive applications. Capable of supporting a wide range of materials including highly reflective metals, demonstrating excellent quality results. - Productive

The modular and adjustable design of the nozzles offers differing build rates and freedom in either fabrication or reworking. - Accurate

Specific attention to mechanical and optical alignment resulting in axis accuracy and volumetric precision. Excellent quality and process dynamics even with the highest z-resolution and hatching distance. - Profitable

Low investment and maintenance cost along with a wide network for materials, consumables and spare parts. - User Friendly

Easy to use programming software for definition of scanning path and slicing along with Prima Additive intuitive operator interface.