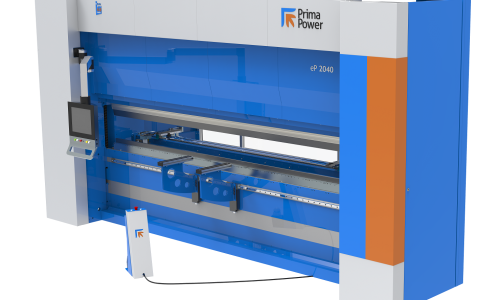

Prima Power eP Genius press brake combines servo-electric bending combined with a sizeable automatic tool change system. For this reason, it offers a versatile, fast, and reliable bending solution and significantly reduces the manual setup of the machine. As a result, it allows the operator to commit their time and skills to the preparation of bending batches.

In short, the Prima Power eP Genius press brake is the perfect combination of tonnage (105 tons) and work capacity (3,060 mm of bending length), automatic CNC crowning, multi-axis back gauges, and IRIS Plus angle control system on CNC-controlled motorized arms.

Prima Power eP Genius Auto Tool Change system.

The Prima Power eP Genius press brake tool storage is the main difference of this product and can accommodate 32 meters of press brake tooling. The tools are placed on eight tool-holder supports that automatically move on three independent axes. The system can handle Wila-style tools with a minimum length of 20 mm up to 515 mm. Furthermore, a rotating turret rotates the press brake tools taken from the storage, granting multiple processing possibilities.

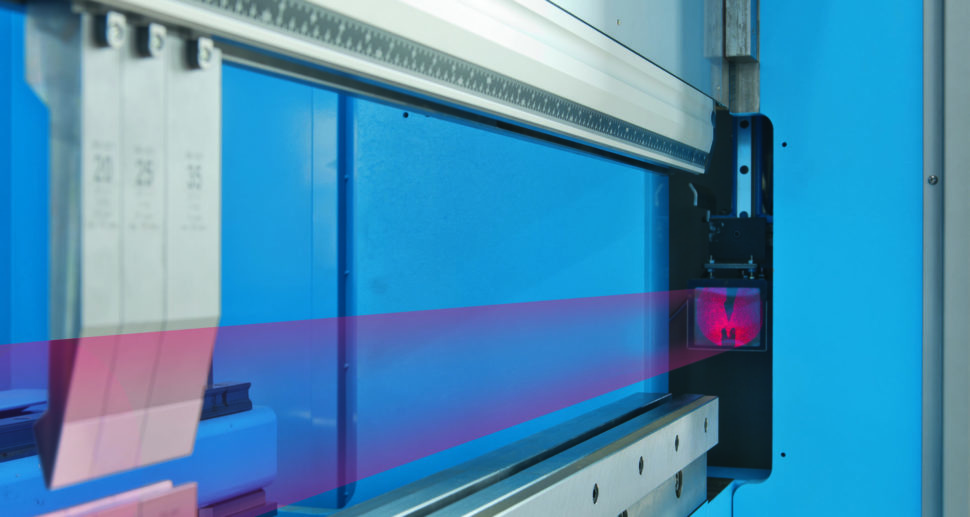

Pulley-belt force transmission

Servo-electric drives actuate the Prima Power eP Genius press brake pulley belt system. With this in mind, the system distributes the bending force over the whole bending length, reducing the need for crowning allowances.

The system consists of fixed and moving rollers spread over the total working length of the upper beam. Unlike other solutions, it is not a tooth style belt, nor is it based on friction. Still, the entire force is transmitted through tension – a simple and especially reliable solution. Furthermore, the belt itself is, in fact, a steel wire reinforced maintenance-free belt.

As a result, the absence of hydraulic oil eliminates thermal influences on the system’s precision.

In addition, the latest-generation Prima Power HMI allows the programming of the workpiece simply and intuitively, both on the machine and off-line, and automatic management of the machine setup.

Prima Power press brake, eP Genius highlights

- Safe, ergonomic & automatic – A laser scanner monitors the machine’s working area, therefore granting complete protection to the operator.

- Ready to produce – Coupled with an automatic tool change system, the machine is always ready to produce compared to press brakes with manual setup.

- Accurate – Reduced possibility of human mistakes, specifically relating to manual tool change and set-up.

- Flexible – Programming and production of kits, as well as of small production batches.

- User-friendly – Easy to program, therefore, easy to use and maintain.