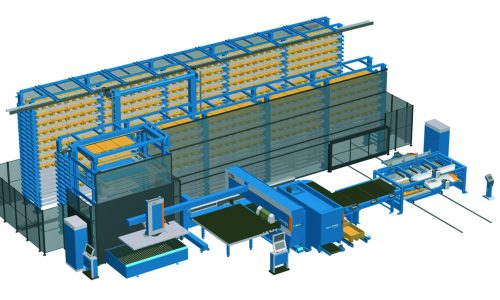

Prima Power Shear Genius – Integrated Turret Punching & Shearing – One Smart Solution

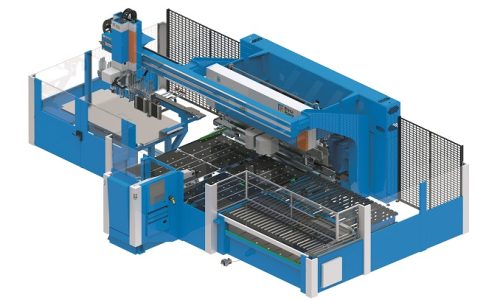

The Prima Power Shear Genius combines punching, shearing, and part handling into a single, compact machine. It transforms raw sheets into finished parts without the need for costly and space-consuming material handling between operations. By eliminating intermediate steps like manual transfer and multiple machines, Shear Genius delivers significant savings in material, floor space, tooling, and energy use.

This all-in-one solution is ideal for a wide range of applications, including sheet metal parts, HVAC components, doors, and electrical cabinets. Trusted by manufacturers worldwide, it performs equally well in standalone cells, automated material handling systems, and even full factory-wide FMS environments.

Servo-electric technology gives Shear Genius a clear edge over hydraulic systems, delivering superior punching force, speed, and accuracy while using up to 65% less energy. This makes it the perfect choice for modern, energy-conscious manufacturing facilities.

Prima Power Shear Genius key advantages include:

-

Exceptional punching and shearing performance

-

Up to 65% energy savings compared to hydraulic systems

-

Faster cycle times and reduced production costs

-

Smaller environmental footprint

Prima Power has been at the forefront of servo-electric innovation for over 20 years, driving sustainable productivity in sheet metal manufacturing.

Right-Angle Shear – Fast, Flexible, Intelligent

The integrated right-angle shear features a programmable blade height and automatic stroke depth adjustment, ensuring maximum speed and accuracy during shearing operations. The system automatically selects optimal blade speed and adapts shearing modes for faster throughput.

With the longest blades on the market (1000 x 1500 mm), the Shear Genius guarantees reliable part release and fast processing for even the most complex sheet layouts.

Prima Power Shear Genius highlights

- Fast setup with up to 384 tools in the turret at the same time

- Up to 300 kN ( 30 ton ) punching force for demanding products

- Lowest energy consumption on the market – average power consumption 6 kVA / 5 kW

- Low maintenance cost

- High versatility

- A wide range of modular automation options can also be installed later as machine upgrades

- No skeletons, less punching scrap = savings in raw material