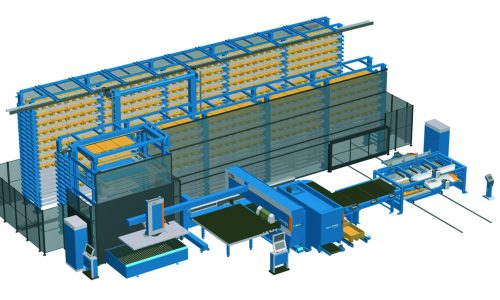

The Prima Power PSBB line is a highly efficient automated system for processing sheet metal that continuously performs punching, shearing, and bending without intermediate manual handling.

The PSBB (Punch-Shear-Buffer-Bend ) line integrates several advanced Prima Power machines into a complete Flexible Manufacturing System ( FMS ).

Prima Power PSBB includes:

Combining these machines creates a seamless workflow and optimises the production process from punching and shearing to bending and stacking.

This line offers several advantages, including:

On-Demand Production: It enables the production of parts as needed to reduce inventory costs and increase flexibility.

Just-in-Time Manufacturing: The PSBB line minimises lead times and aligns production closely with demand by producing what is required when needed.

Reduced Lead Time: The seamless flow of operations minimises delays, ensuring quicker turnaround times from raw material to finished product.

Multi-Material Processing: The ability of the PSBB to handle different materials without retooling reduces downtime and enhances versatility.

Flexibility: Add modular automation in stages to grow with production requirements.

Highlights of the Prima Power PSBB

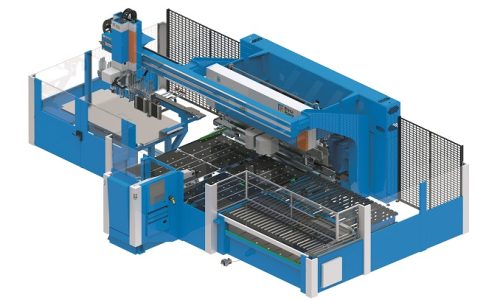

- Versatile servo-electric punching

- Integrated servo-electric shearing

- Servo-electric bending

- Automatic, flexible material flow and

- Sophisticated software

- Automatic information flow from programming to production reporting.

- An integrated production system reduces the whole fabrication process into a single one.

- Automatic material handling including intelligent buffering.

- Minimum manufacturing time, maximum production time.

- Optimal value stream from raw material to ready-made components.