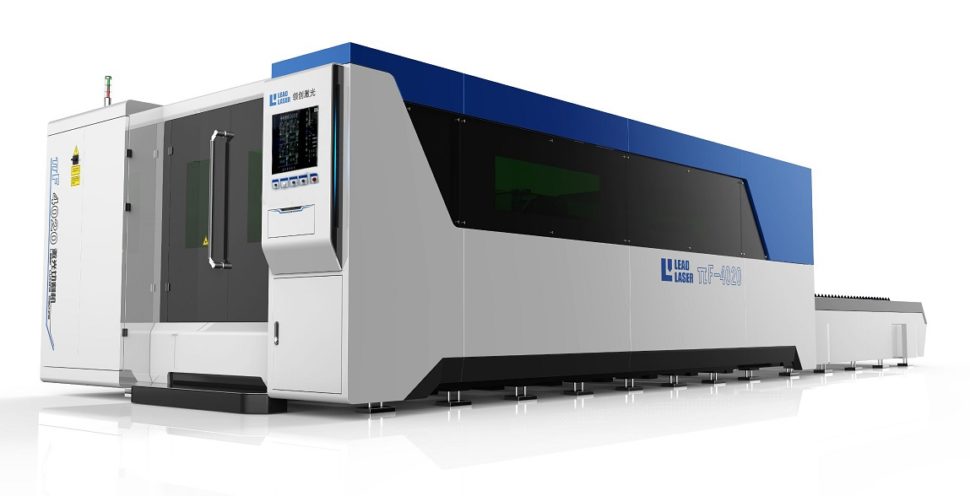

The LF laser cutting systems from Lead Prima are purpose-built for mid-range plate cutting, supporting sizes from 4m x 2m up to 8m x 2.5m. Designed to handle laser powers of up to 20kW, the LF series combines precision engineering with cost-effective operation, making it an ideal choice for manufacturers seeking high productivity without compromising on budget.

The LF range features a lightweight aluminium Y-axis gantry, enabling rapid acceleration and repositioning speeds while maintaining exceptional repeatability and tight positioning tolerances.

Each system includes an automatic transfer table for uninterrupted production and is enclosed in a CE-certified Class 4 safety cabin, ensuring full compliance with European safety standards and maximum operator protection.

Some highlights of the LF laser cutting system

- Integrated gantry structure with dual AC servo motors for high-speed synchronous drive

- Lightweight, high-strength aluminium alloy beam and Z-axis slide plate for superior dynamic performance

- Advanced European CNC control system with laser-specific cutting functions

- German-engineered precision components including linear guide rails, reducers, and anti-backlash helical gear transmission for high accuracy and stability

- Zoned dust extraction system for long-term operational reliability

- High-speed mechanical double exchange worktable for continuous workflow

- Optional ICS (Intelligent Cutting System) for enhanced cutting quality and process control

- CE-certified Class 4 safety enclosure for full compliance and operator safety

- Affordable performance—designed to deliver high-end capabilities at a competitive price point