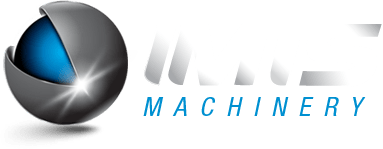

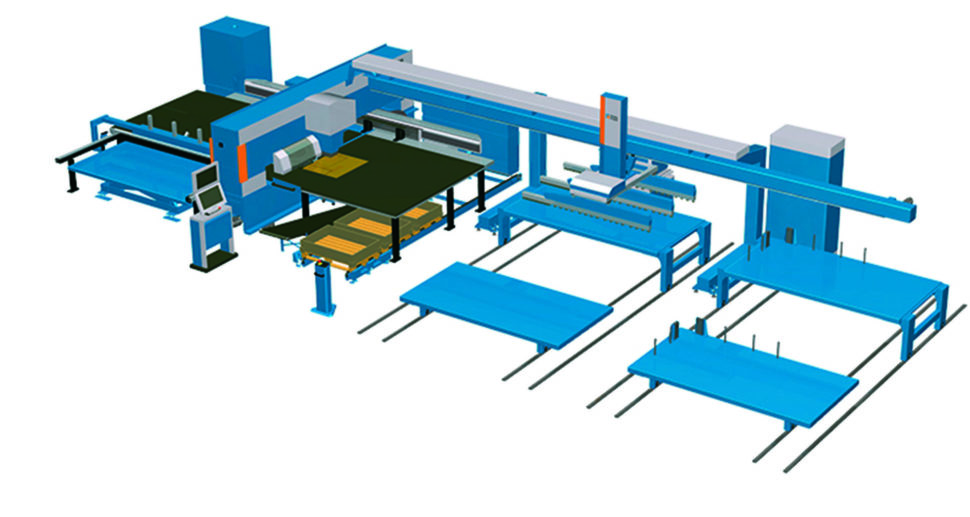

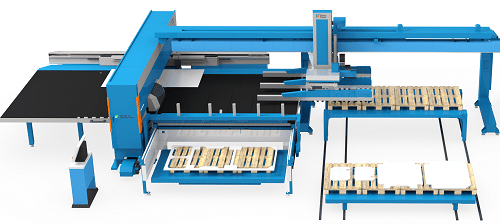

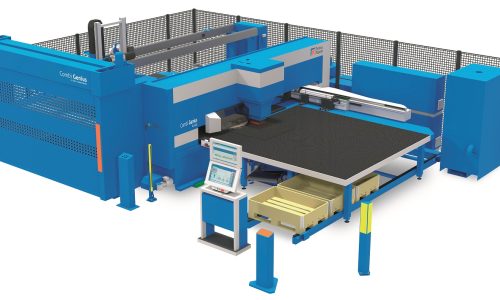

LST is a compact high-performance automatic loading and stacking robot. LST loads the sheets into the machine, picks the parts and sorts them to stacks to use in following process steps. The entire working cycle of the machine is automatic.

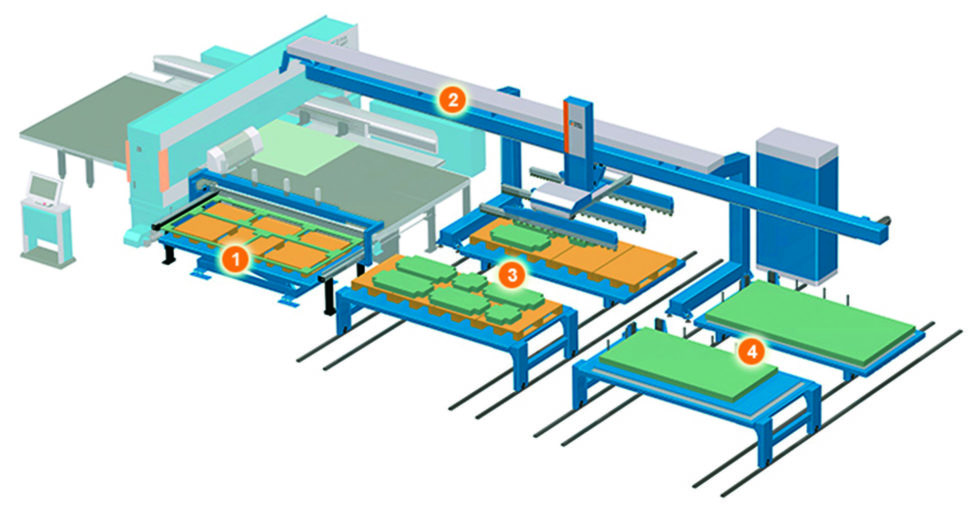

Sheets are loaded from a loading position into machine clamps. Double sheet detection can be performed for every sheet.

Punched or laser cut parts are picked up in front of the turret or from cutting head by a pneumatic gripper. The parts are stacked on the programmed positions on the palletizing area of stacking table, wagon or storage cassette.

Skeletons are unloaded by the unloading device UDC integrated to machine table. UDC locates at the A-side machine table with laser punch combination machines and at B-side with punching machines.

There are two versions available of LST, short LST/S and long LST/L. The differences are with the length of the main frame and number of fixed loading/stacking table or wagon positions

Some highlights of the LST Loading and Stacking Robot

- Symmetrical gripper bars allows better picking opportunities

- Part picking functions are available

- Pre-sorting is a default function

- RALC function (Robot Assist Last Cut, LST gripper will hold the part when its last edge is cut) is possible when part/working area allows it

- Active detection for part detached from skeleton to improve continuous and reliable process