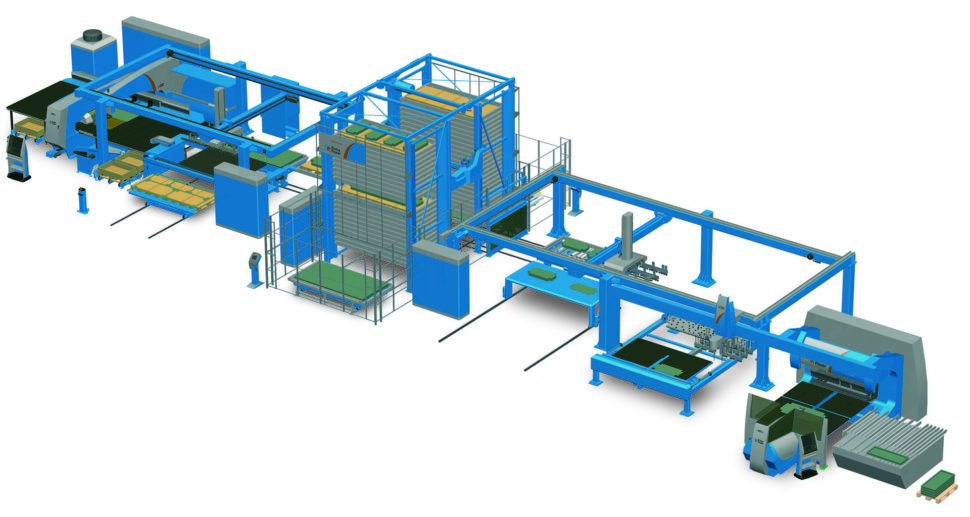

Combo Tower is a flexible storage solution to automating the material flows.

It makes different materials available whenever needed automatically and without delays; it can also serve as an intermediate storage for ready components and as a buffer.

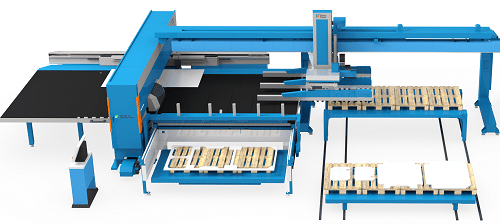

There can be one or two shelving units in the Combo Tower storage and height can be chosen by needs. From one to three machines or cells can be integrated in the system; depending on the required work stages and techniques, these are selected from the wide range of Prima Power solutions for punching, laser cutting, integrated punching / shearing and punching / laser cutting

Some highlights of the Combo Tower CT

- Highest load and unload speed on the market

- Load and unload into one tower with up to 24 shelves

- Source parts from within the shelving unit with a simple search without disturbing the rest of the operation ( with optional IOW )

- Height of system and amount of shelves are only governed by customer roof height

- Up to 3 tonne of material in each shelf at any one time

- Double towers increase cassette amount

- Connect up to 2 machines to same tower