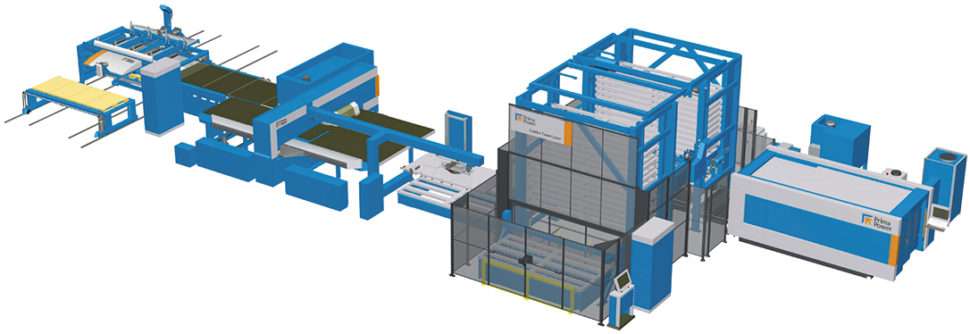

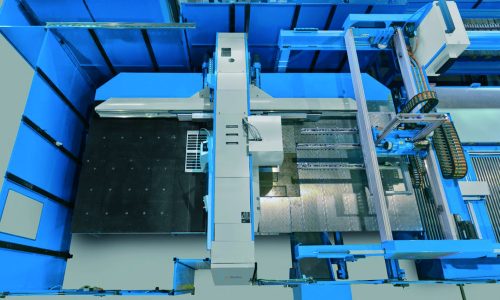

Combo Tower Laser is a flexible storage system with integrated loading and unloading features for 2D lasers.

Combo Tower Laser is a flexible storage system with integrated loading and unloading features for 2D lasers. Combo Tower Laser is a key module to automate material flow. It makes different materials available whenever needed automatically and without delays; it can also serve as intermediate storage for ready cut components along with skeleton.

Combo Tower Laser also provides an optimal solution for lights-out production as capacity of available raw materials and unloading positions for skeletons can be updated to meet production requirements.

When two shelving units are included in the Combo storage a second machine cell can be integrated as part of the system; depending on the required work stages and techniques, these can be selected from the wide range of Prima Power solutions for punching, laser cutting, integrated punching / shearing and punching / laser cutting.

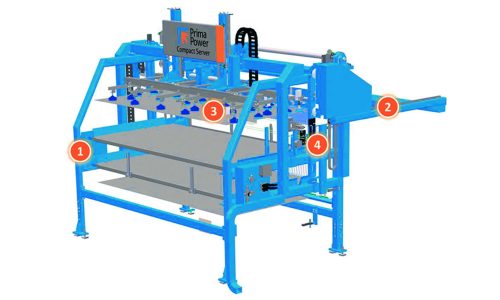

Some highlights of the Combo Tower Laser CTL

- Highest load and unload speed on the market

- Ability to add a second tower and connect a punching machine with material coming from either tower to the machines

- Load and unload into one tower with up to 24 shelves

- Source parts from within the shelving unit with a simple search without disturbing the rest of the operation ( with optional IOW )

- Height of system and amount of shelves are only governed by customer roof height

- Up to 3 tonne of material in each shelf at any one time