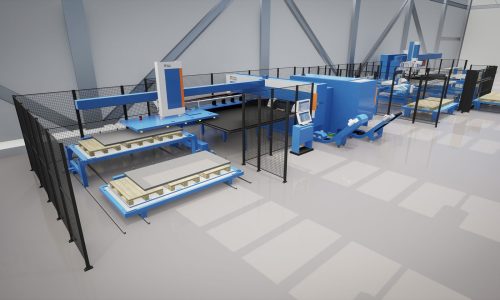

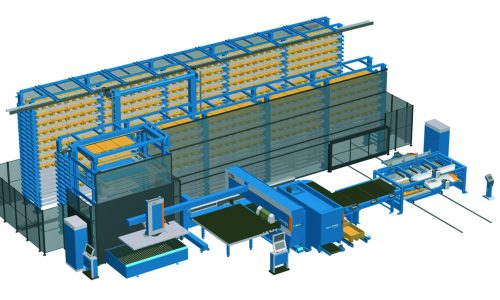

Prima Power Shear Genius, moreover, provides one machine capable of transforming parts to final production stages without requiring costly material handling solutions between loading, punching, shearing, sorting, and unloading. As a result, the Shear Genius concept saves material, overall floor space, investment in separate machines, tooling, and finally, energy use.

Extensively used throughout the industrial world in varied applications such as sheet metal parts, doors, HVAC components, and electrical cabinets, the Prima Power Shear Genius is the proven solution. Either within independent production cells or as the central unit within an automatic material handling system, and finally up to a factory-wide FMS level.

Servo-Electric Punching and Shearing Technology

Servo-electric machines by and large outperform hydraulic machinery when punching tonnage, punching speed, and accuracy are necessary. In particular, energy efficiency is an essential requirement for modern production facilities; therefore, with 65% less power usage, Prima Power Shear Genius servo-electric technology is the ideal solution for manufacturing sheet metal components.

In short, the Prima Power Shear Genius servo-electric technology provides:

- Outstanding overall bending results.

- Extremely high energy efficiency.

- Instant reduction in production cycle times.

- Finally, reducing the environmental footprint.

Generally speaking, punching and shearing combination technology generally use hydraulic solutions. In addition, hydraulic punching and shearing machines require large cooling systems to cool the hydraulic oil. These large cooling systems are therefore expensive to run and maintain.

For this reason, Prima Power has proven to be immediately ahead of their opposition, applying the servo-electric concept to its machines more than 15 years ago. Prima Power introduced this critical technology to provide sustainability, manufacturing efficiency, and productivity.

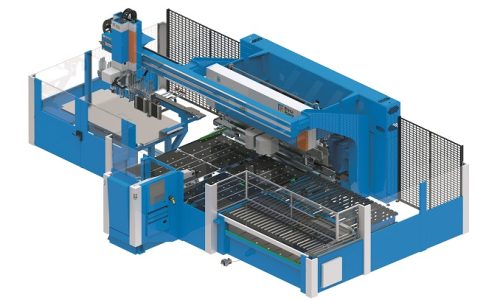

Prima Power Shear Genius Right- Angle Shear

The Prima Power Shear Genius right-angle shear is extremely fast in its operation. In addition, programmable blade height and automatic stroke depth adjustment combine to allow a high-speed shearing process. Further, shear blade speed, automatically selected for the maximum speed possible for production capability. As a result, combined with automatic shearing modes, these features optimize the machine’s overall operation speed.

By and large, the shearing process is the most reliable method for part separation from the sheet. When the shear blades are in the lower position, it is therefore 100% sure that part is released with high quality, making this technology a key factor for 24/7 production. Finally, the Prima Power Shear Genius has the longest shearing blades available ( 1000 x 1500 mm ) for fast and reliable part release to the following process.

Prima Power Shear Genius highlights

- Fast setup with up to 384 tools in the turret at the same time

- Up to 300 kN ( 30 ton ) punching force for demanding products

- Lowest energy consumption on the market – average power consumption 6 kVA / 5 kW

- Low maintenance cost

- High versatility

- A wide range of modular automation options can also be installed later as machine upgrades

- No skeletons, less punching scrap = savings in raw material