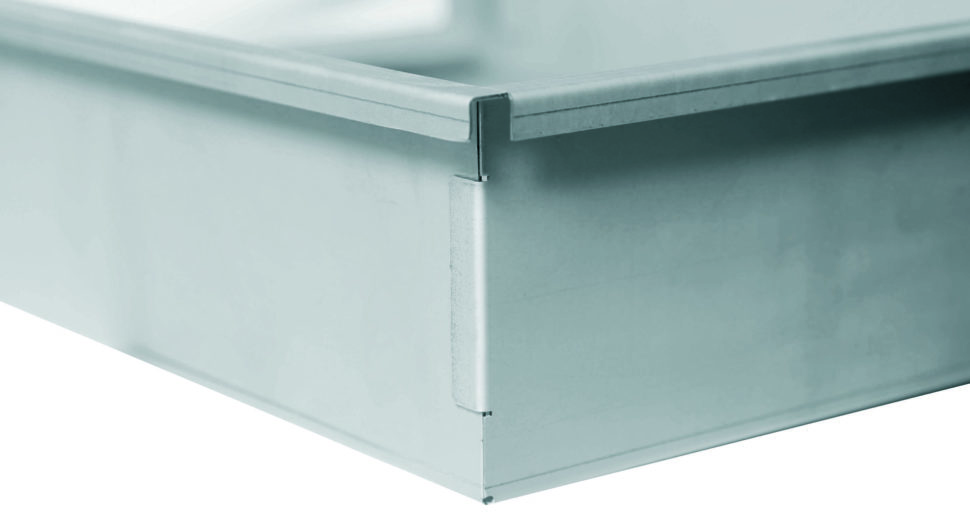

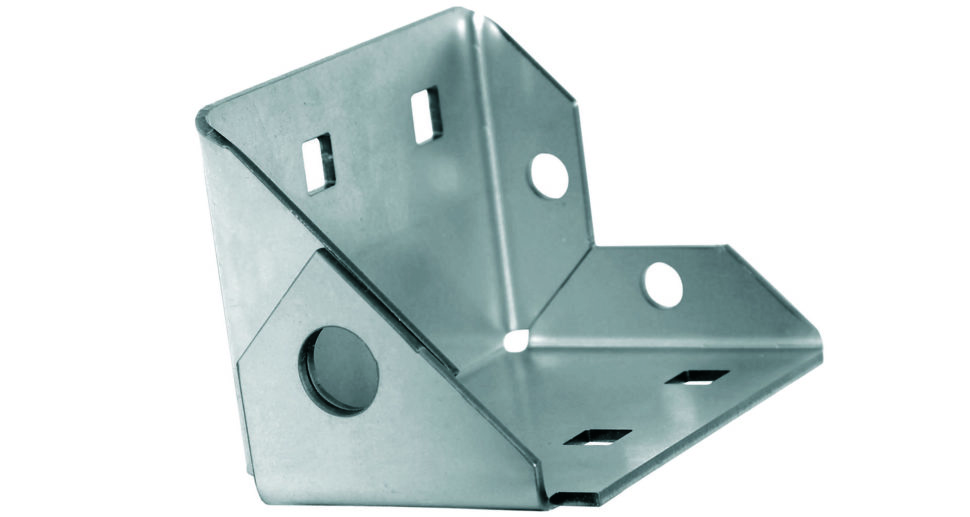

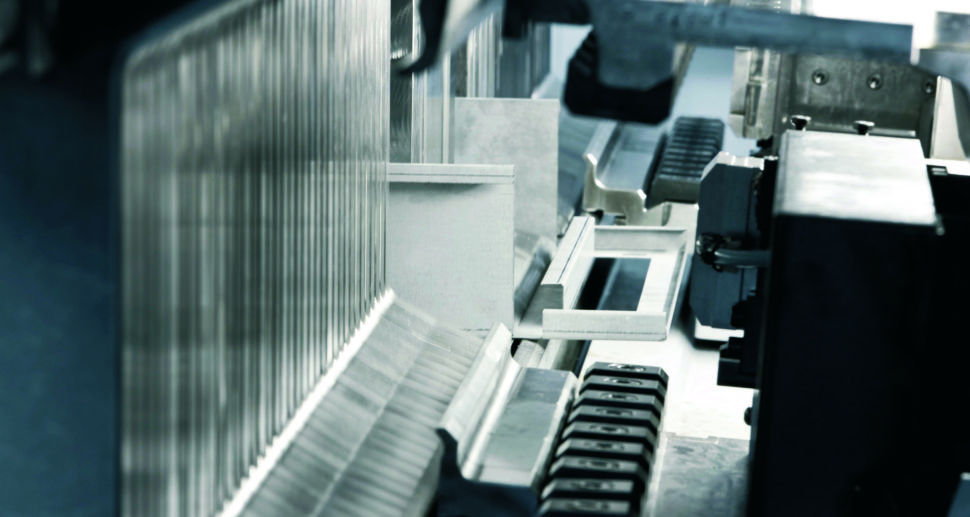

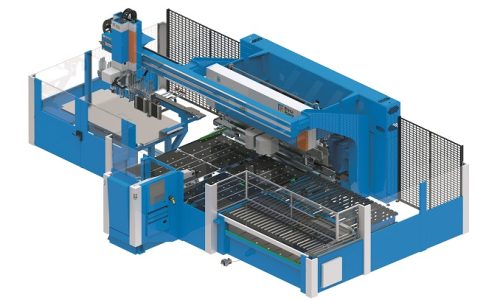

Prima Power Fast Bend Panel Bender replaces the traditional press brake with an automatic bending technology, which allows more bends for each side in an automatic sequence without any manual intervention, including positive/negative bending, smash bends and radius bends. Only the loading, rotation, and unloading are performed by the operator.

The result is quality, speed, and elimination of mistakes.

The machine can be operated in two different modes :

- Standard mode, the part is automatically fed during the bending sequence of every side,

- Press brake mode, the sheet is moved bend-by-bend manually, thus allowing the processing of very narrow profiles.

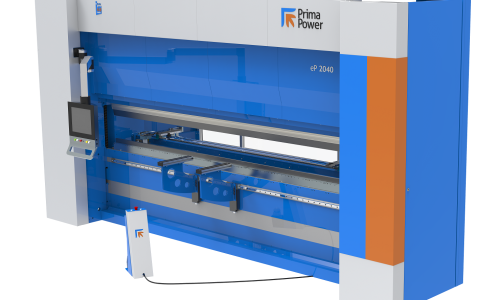

PRECISE

Excellent bending quality thanks to the standard corner correction database and servo-electric technology.

ACCESSIBLE

The additional monitor and barcode or QR reader all support the operator in machine interaction.

FLEXIBLE

Suitable for bending various types of pieces.

EASY

3D programming with integrated simulation of the bending cycle.

Some highlights of the Fast Bend Panel Bender FBe

- Excellent quality of the bent component

- Lower cost of the tools

- High reliability

- Easy and intuitive programming

- Servo-electric bending with air cooling

- No influence by thermal conditions

- Possible upgrade with industrial robot

- Favourable energy saving

- Very low maintenance costs

- Reduced impact on the manufacturing environment with minimum noise and vibrations