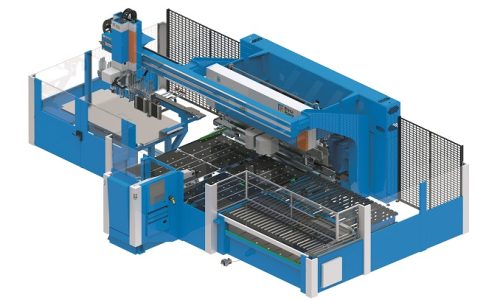

Prima Power has applied a servo electric drive system to the eP-Series press brakes – a fast, accurate, non-hydraulic bending solution.

With more than 20 years of experience in applying servo electronics in sheet metal working, the Prima Power eP-series press brakes meet customers’ expectations for bending medium-thin sheet metal.

Prima Power eP-series press brakes are the optimal solution for manufacturers of HVAC, metal furniture, white goods and domestic appliances, facades, electrical cabinets, and all applications which need fast and accurate machinery to help increase productivity.

The servo-electric concept combines productivity, accuracy, flexibility, and reliability with high respect to ecological aspects – Prima Power calls this concept “Green Means®”

The concept offers you both sustainability and manufacturing efficiency and productivity. It means greater versatility, lower power consumption, virtually no maintenance, and no oil to replace or dispose of – better for the customer and the environment.

Highlights of the Prima Power eP press brake range

- Energy saving – Average 60% lower consumption than traditional hydraulic press brakes

- Productivity – 30% shorter cycle times on average and short setup times

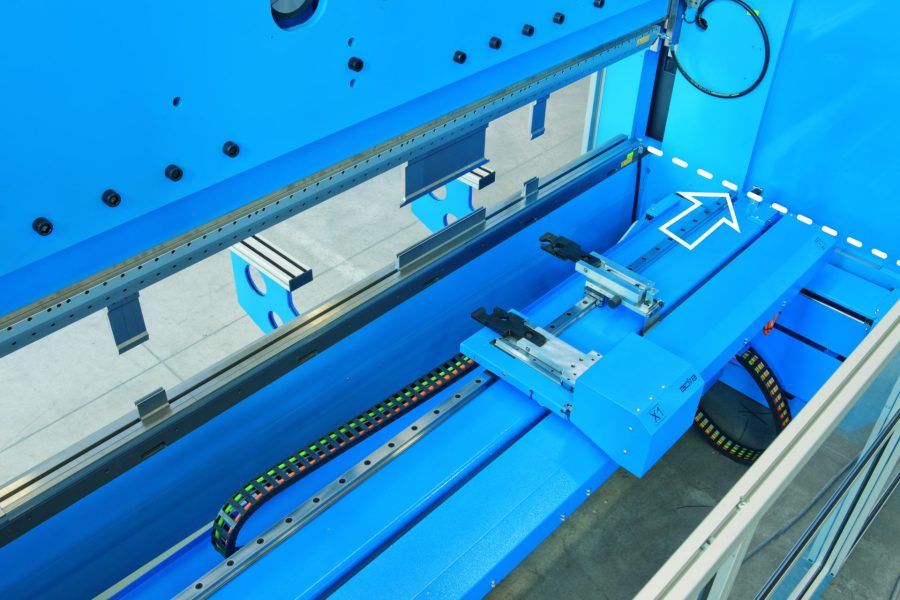

- Part quality – High repeating accuracy thanks to O-frame construction, servo-electric drives, sophisticated tooling system

- Low maintenance cost – Fewer critical components than in hydraulic machines

- Block Laser safety equipment – most advanced solution in terms of productivity and protection level

- Angle measurement option – high-speed digital image processing technology to measure the angle of the formed workpiece on every cycle with automatic correction of the bend program

- AQ-bending follower optional – no need for a second operator for supporting large parts

- Wila or Euro style tooling system – quick, accurate and flexible