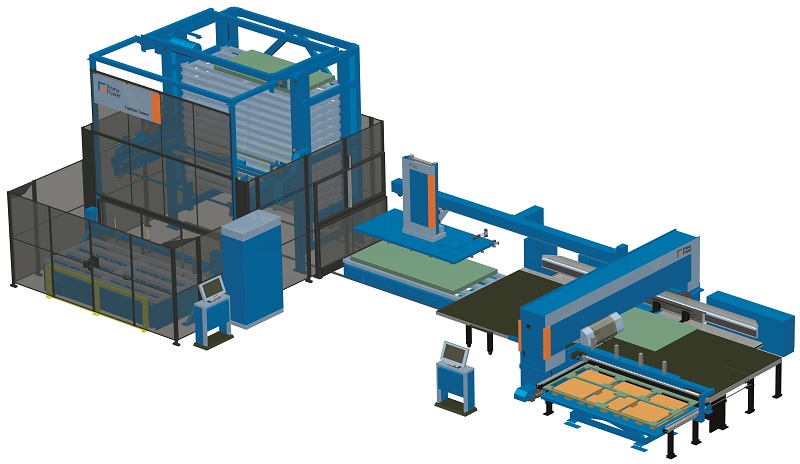

Punch Genius Turret Punch -Designed for Smart Manufacturing

The Punch Genius turret punch lives up to its name by combining intelligent features with a space-saving footprint. This servo-electric turret punch press delivers superior productivity, flexible automation compatibility, and user-friendly operation—all driven by real-world industry requirements.

With decades of experience in turret punch press technology dating back to the early 1980s, Prima Power understands what fabricators truly value—ease of use and high productivity. Drawing from this deep expertise and real customer feedback, they developed the Punch Genius, a compact yet powerful punching solution designed to meet the evolving needs of modern sheet metal manufacturers.

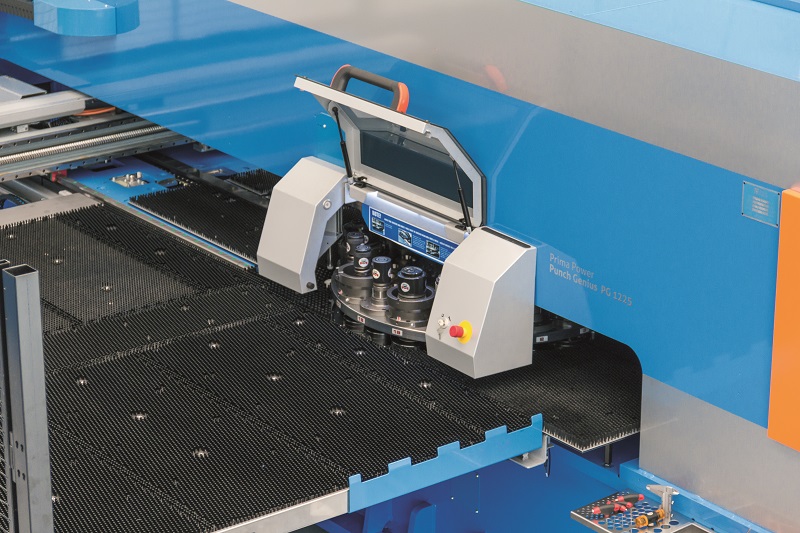

At the heart of the machine is a modern central control unit with a touchscreen interface powered by the Tulus® operating system, making machine setup, job scheduling, and monitoring intuitive and efficient. When combined with NC Express CAM software, users gain access to detailed production and performance reports and seamless integration with ERP systems, ensuring total production transparency.

Advanced Technology for Modern Demands

The Punch Genius is equipped with numerically controlled, servo-electric axes, providing:

-

High speed and precision

-

Exceptional energy efficiency

-

Low maintenance costs

Its productivity is further enhanced by:

-

Large tool capacity

-

Extensive tool range

-

Quick and easy setup changes

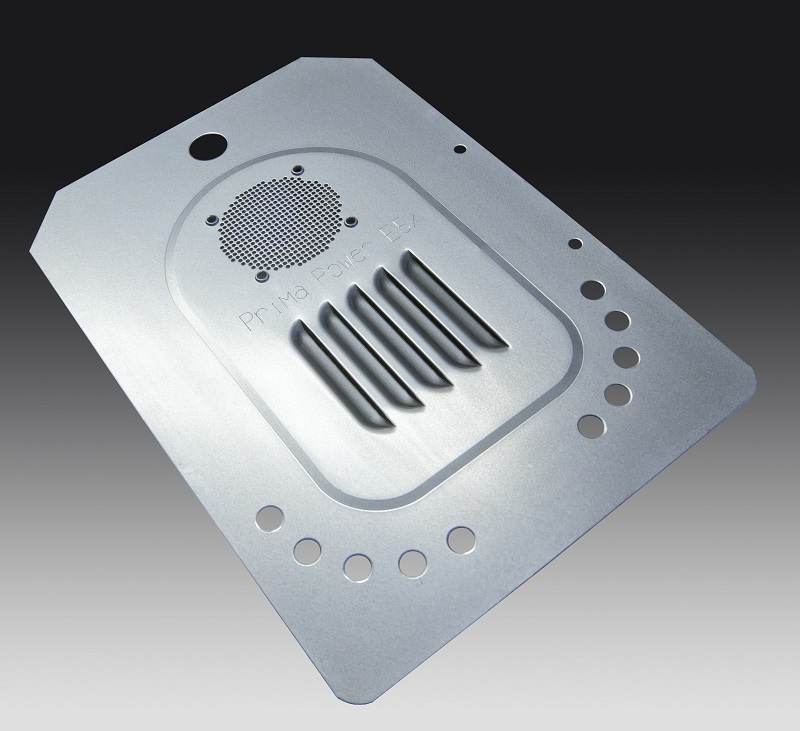

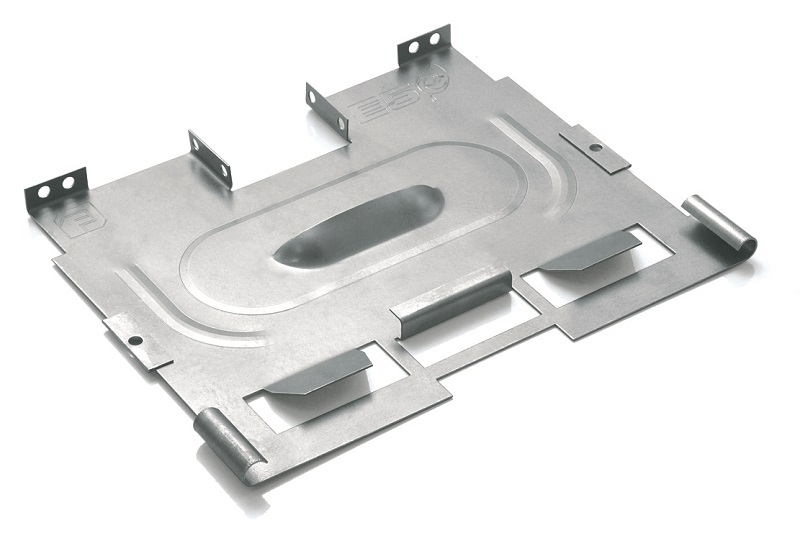

Additionally, built-in capabilities for forming, tapping, and marking allow multiple operations in a single setup—streamlining production and reducing the cost per part.

Punch Genius by Prima Power is not just a turret punch press—it’s a smart, scalable, and competitive manufacturing solution for forward-thinking fabricators.

Punch Genius Turret Punch – Key Features

-

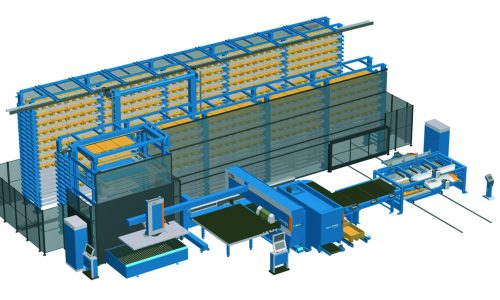

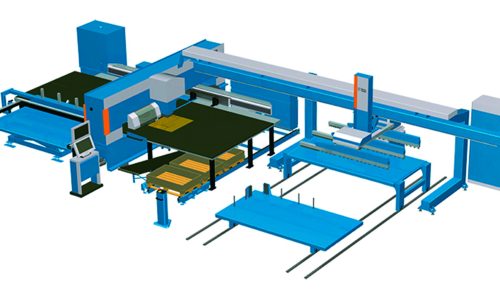

Flexible Loading Options

Manual sheet loading available from either the A-side or B-side, or fully automated with optional automation cells for increased efficiency. -

Energy-Efficient Operation

Advanced servo-electric punching technology offers up to 60% lower power consumption compared to traditional systems, significantly reducing operating costs. -

Maximized Sheet Utilization

The Programmable Clamp Setting (PCS) enables individual clamp movement, allowing for 100% sheet usage and minimal material waste. -

Scratch-Free Processing

Vertical-moving automatic brushes protect the underside of the sheet during punching and forming, ensuring a high-quality, mark-free finish. -

Powerful Upforming Capability

A 22-tonne upforming cylinder enables the creation of a wide variety of complex forms directly within the punching process. -

Smart Mobile Integration

The Tulus® Mobile app (Android-based) provides real-time operational assistance, including tool setup guidance and machine status monitoring for enhanced productivity and usability