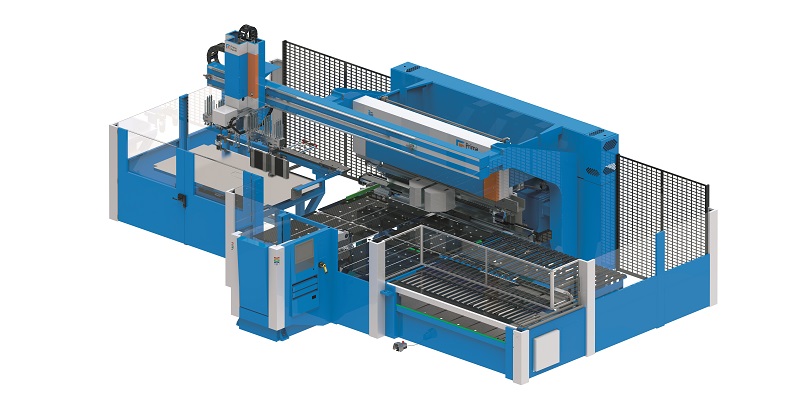

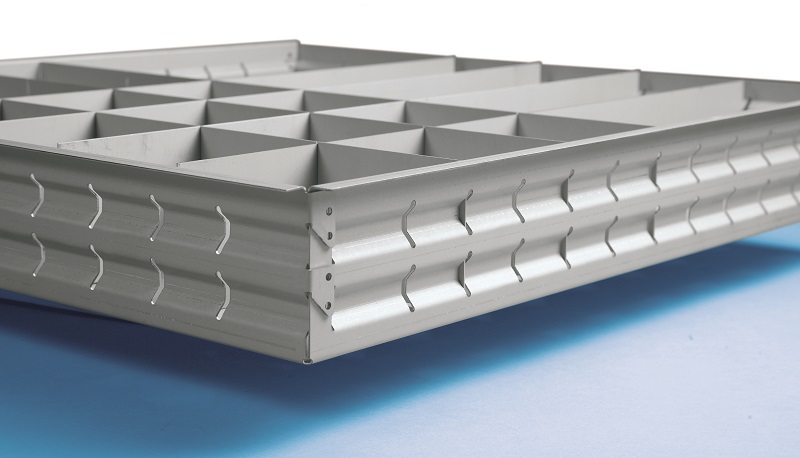

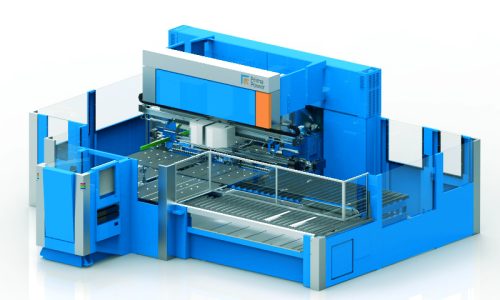

Prima Power’s Express Bend panel bender is the servo-electric panel bender that considerably increases production capacity thanks to the automated loading and unloading process, thus maximizing the efficiency of the bending process. In the stand-alone version, the system includes a loading table for large quantities of the same part: this configuration is suitable for larger production volumes with limited variability.

The PCD wagon device is an alternative with greater automation when loading several stacks of different pieces – with an optional turning device – which allows batch or kit production and prepares the panel bender for future connection with other Prima Power machines.

PRECISE

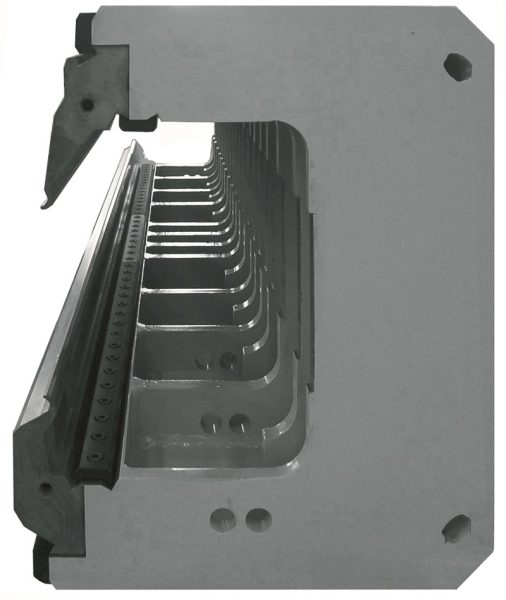

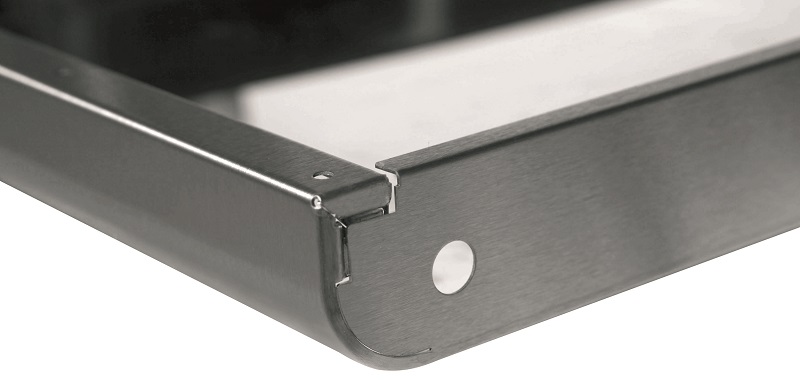

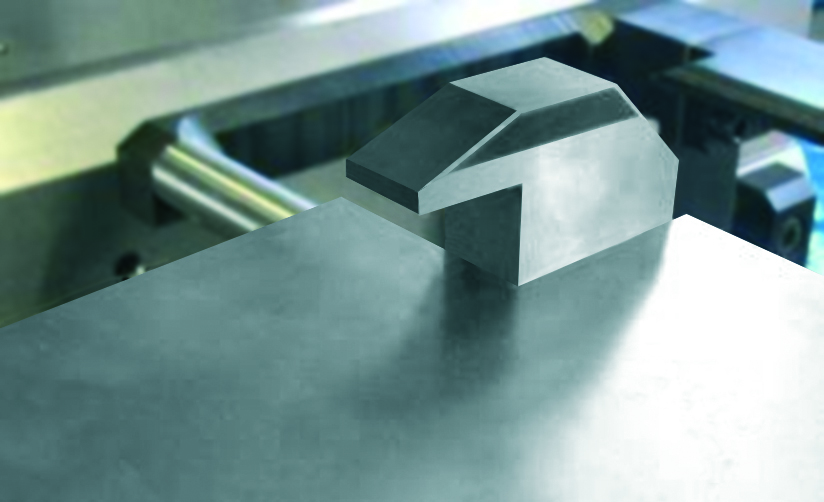

Excellent bending quality thanks to the angle correction database and servo-electric technology.

SCALABLE

Suitable for every production requirement thanks to the complete range of automation, loading and unloading solutions.

FAST

Reduction of cycle times with loading and unloading operations in masked time.

EASY

3D programming with integrated simulation of the bending cycle.

Express Bend panel bender characteristics

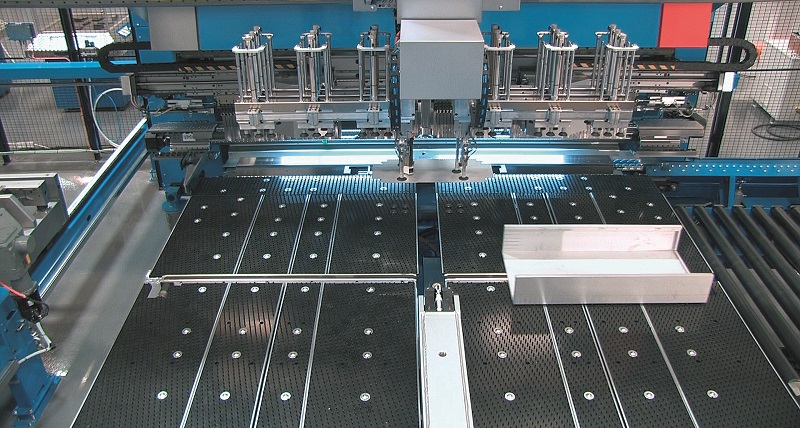

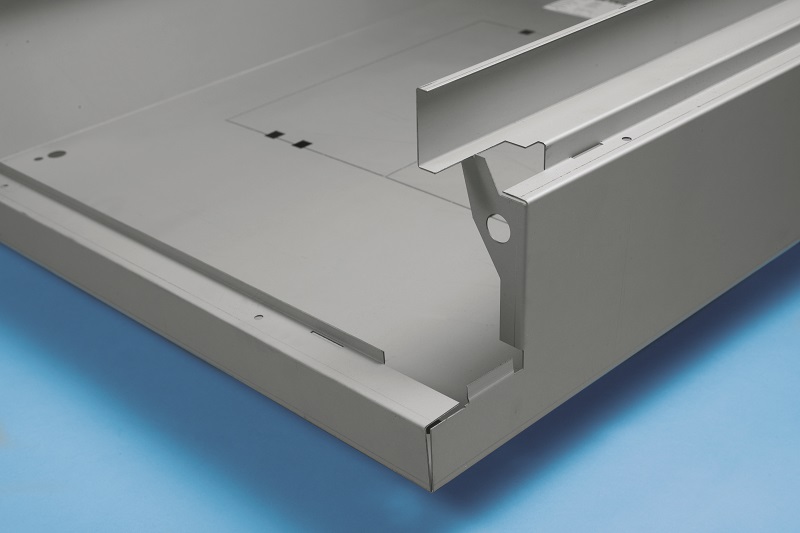

- Stack loading system with automated loading gripper based on suction cups

- Loading operation is made during the bending cycle, and the new panel is positioned in a standby position over the manipulator

- An automatic conveyor unloads bent components to a free-roll table

- Fully automated set-up between different components (with ATC option)

Highlights of the Express Bend

- High productivity and faster programming utilising automatic loading and unloading

- Low tooling costs

- Excellent component repeatability

- Increased range of bending profiles using servo-electric technology

- Electrical energy savings

- Maintenance costs reduced

- Low noise level